The application of high-tech new ceramic materials in large-diameter industrial valves. Currently, metal valves are commonly used in various industries in China. The use of metal valves has a history of over a hundred years. Although they have also undergone structural and material improvements, due to the inherent conditions of metal materials, they are increasingly unable to adapt to harsh working conditions such as high wear and strong corrosion. Mainly reflected in the short service life and severe leakage, which greatly affects the stability of system operation. Traditional metal valves urgently require innovation in materials, design, and manufacturing processes.

Advanced ceramic materials, as new materials in the 21st century, have been increasingly valued by more and more scientific workers. Applying them to industrial valves is a bold and beneficial innovation. Today's focus: ceramic materials have very small deformation and much higher bonding strength than metals. Generally, the crystal Ionic radius of ceramic materials is small, and the ion electricity price is high, and the Coordination number is large. These properties determine that the tensile strength, compressive strength, elastic modulus, hardness, etc. of ceramic materials are very high. However, the "brittleness" of ceramics itself and its application scope are difficult to machine. In the past ten years, due to the development and progress of Martensite transformation toughening technology, composite material technology and ceramic concept, the "brittleness" of ceramics has been greatly improved, its toughness and strength have been improved, and its application scope has continued to expand.

In recent years, the application of new ceramic materials in fields such as petroleum, chemical engineering, and machinery has been very active. Utilizing the wear and corrosion resistance of ceramics to make wear-resistant and corrosion-resistant parts instead of metal materials has been one of the important development directions in the high-tech material market in recent years.

The following key issues need to be addressed in the application process of ceramics: solving the brittleness problem of ceramics and improving their toughness; Control the shrinkage rate and improve the firing yield of ceramic materials; Develop and develop high-temperature kilns; Develop ceramic processing equipment; Realize the coordination between ceramic parts and metal valve bodies. Tianjin Pressure Reducing Valve Technology Development Co., Ltd. has conducted research on the key issues mentioned above and has achieved solutions. After trial production, it has been widely used by manufacturers in multiple industries such as power, metallurgy, and chemical engineering.

Ceramic valves, huge socio-economic benefits:

1. The use of high-tech new ceramic structural materials to make sealing and vulnerable parts of valves has improved the wear resistance, anti-corrosion and sealing properties of valve products, greatly extending the service life of the valve.

2. The use of ceramic valves can greatly reduce the maintenance and replacement frequency of gate valves, improve the stability of supporting equipment operation systems, reduce labor intensity of workers, and save equipment repair costs.

3. The use of stop valve porcelain valve can improve the tightness of industrial Plumbing, and at the same time, it can prevent leakage to a certain extent, which will promote environmental protection.

4. The raw materials for manufacturing ceramics are extensive and the cost is low. Using ordinary elements such as aluminum, carbon, and silicon can produce high-performance ceramic materials, which can save a lot of metal materials and rare mineral resources.

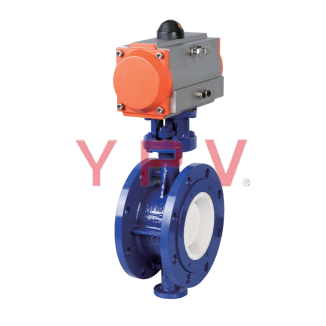

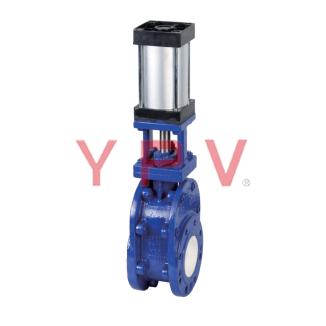

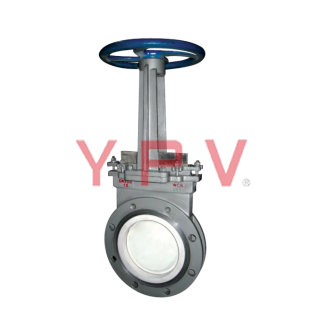

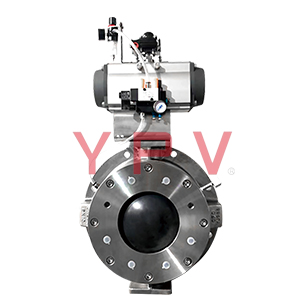

Wear-resistant ceramic valves are mainly used in industrial fields such as electric plug valve oil, chemical industry, metallurgy, mining, sewage treatment, etc., especially in the face of harsh working conditions such as high wear, strong corrosion, high temperature, and high pressure